無料ダウンロード qq-p-416 type 2 class 2 343951-Qq p 416 type 2 class 1

QQP416 Because of health hazards, THIS PROCESS IS NOT RECOMMENDED A coating for ferrous metals Bright silvery white Supplementary treatments for TYPE II can be golden, iridescent, amber, black, olive drab Corrosion resistance is veryTable II Standard Finishes Master Table Glenair Symbol Finish Specification(s) A Cadmium Plate, Bright AMSQQP416, Type I, Class 2 B Cadmium Plate, Olive Drab AMSQQP416, Type II, Class 3 C* Anodize, Black AMSA8625, Type II, Class 2 G* Hard Coat, Anodic AMSA8625, Type III, Class 1 J Iridite, Gold Over Cadmium Plate Over Electroless NickelSPECIFICATION QQ – P – 416 / AMS – QQ –P – 416 Class 1 THICKNESS" min Class 2 THICKNESS" min Class 3 THICKNESS000" min Type I DETAIL As plated, no chromate Type II DETAIL With supplementary chromate treatment (SPI provides clear, gold and olive drab chromate) Type III DETAIL With supplementary phosphate treatment (This service is not offered

Seastrom Mfg Com

Qq p 416 type 2 class 1

Qq p 416 type 2 class 1-2 (Class 1A &Multichrome/ Microplate processes Type I and Type II cadmium plating conforms to industry standards AMSQQP416;

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

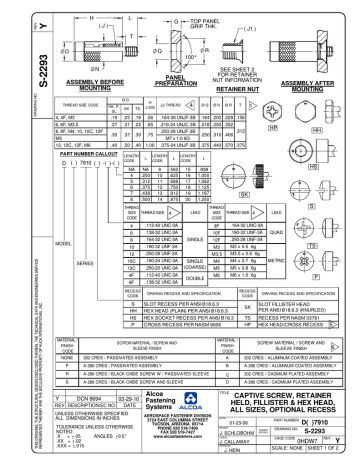

THREAD AS79 MATERIAL Carbon steel per AMS5085, heat treated Rc 49 max FINISH MK1000(*) Cadmium plate per AMSQQP416, Type II, Class 2, plus dry film lubricant coat per AS5272, Type I MK1000(*)CW Cadmium plate per AMSQQP416, Type II, Class 2, plus polyethylene glycol 8000Cadmium Plate w/Chromate Dip, AMSQQP416, Class 2, Type II Cadmium plating is used on carbon steel to increase the corrosion resistance of the product The process of cadmium plating spiral retaining rings is costly and subjects the ring to the possibility of hydrogen embrittlementQQP416 AMSQQP416 Class I minimum thickness Class II minimum thickness Class III minimum thickness Type I As plated Type II With chromate treatment Type III With phosphate treatment Colorless Irridescent Bronze Brown Olive Drab Yellow Forrest Green Primarily used to protect steel and cast iron against

THREAD AS79 MATERIAL Carbon steel, heat treated FINISH MF5000(*) Cadmium plated per fed spec AMSQQP416, Type II, Class 2 KaylubeCadmium plate per AMSQQP416 plus an approved lubricant Type and class of plating is optional If lubricated nut will meet the salt spray requirements of AMSQQP416, type II Nut shall conform to NAS3350, class IIINickel Plating We process sulfamate nickel plating class 1 and class 2 with dull or satin finishes that are applied for corrosion protection The nickel plating process can be applied as an

Military Specifications AMSQQP416, AMS 2400, BAC5701, DPS 928, HP 411, PS , PS Classification Type 1 Clear without supplementary chromate treatment Type 2 With supplementary chromate treatment, iridite (gold) and clear Class 1 0005 thick Class 2 0003 thick Class 3 0002 thickSAE AMSQQP416 Plating, Cadmium (Electrodeposited) General Usage The electrodeposited cadmium platings covered by this specification are intended for use as corrosion protective coatings Processes used for cleaning and cadmium deposition on parts SAE AMSQQP416CaD Plate Per aMs QQP416 tyPe ii Cl2 CaD Plate Per aMs QQP416 , tyPe ii Cl2 CPr CaD Plate Per aMs QQP416 tyPe ii Cl2 GreeN Par 90 CaD Plate Per aMs QQP416 , tyPe ii Cl2 Par 90 Or Bare TABLE 1 strength requirements – CCr274 (Class 1), CCr264 (Class 2), CCr244 (Class 3) Rivet Material Head Class

2

Mil B 76 Pdf Document

QQP 416 Class 3, Type II The parts shall be capable of passing a 96 hour salt spray test to white corrosion and a minimum of a 0 hour salt spray test to red rust per ASTM B117 Typically, cadmium plus yellow chromate offered by PEM is 0002″ to minimum of cadmium applied to all significant surfaces6121 Type II temperature llmltatlons Chromate treatments (Type II) should not be used on plated parts that will not be coated and which will be continuously exposed to temperatures in excess of 150°F (66°C) or intermittently exposed for short periods to temperatures of approximately 300°F (149°C) or moreQQP416E Type Class Lot hydrogen embrittlement testing if required (see 442) and sampling Basis metal to be plated Tensile strength or hardness of the basis metal Preplate stress relief to be performed by plating processor (time and temperature) Special features, geometry or processing present on parts that requires special attention

D 7910 Manualzz

119 23 16

Cadmium Type I, II Class 1, 2, 3 AMSQQP416 *QQP416 Electrodeposited Cleaning Surface Treatments MILS5002 TTC490 Chemical/Abrasive High Humidity Testing AMSSTD753 Method 101 Water Immersion AMSSTD753 Method 100 Copper Sulfate AMSSTD753 Method 102 Passivation AMS2700 *AMSQQP35 *QQP35 ASTM A 967 ASTM A 380Passivation of Stainless Steel to QQP35 QQP35 does not cover citric acid passivation services Four active nitric acid passivation services are covered as follows (four inactive methods have been withdrawn) Type I – Withdrawn Type II – 25 v% Nitric, 225 w% Sodium Dichromate, 1130F, Mins minimum Type III – Withdrawn TypeFinish carbon steel cadmium plate per saeamsqqp416, type ii, class 2 aluminum alloy anodize per mila8625 type i, class optional cres passivate per astma967, type ii silver plate per ams2410 or ams2411or cadmium plate per saeams qqp416 type ii, class 2 solid film lubricant per as5272, type i, applied to threads only

2

Surface Finishing Processes Electroplating

174PH CRES per AMS5643 and cadmium plate per AMSQQP416, type II, class 2 CODE A 174PH CRES per AMS5643 and IVD aluminum coat per MILC4, type II, class 3 CODE V 6 AL4V titanium per AMS4928Data found here within are not to be used for the manufacturer, procurement, or use of this product They are for educational proposes only DRAWING(S) PDF Drawing of AN36A SeriesCres passivate per astma967, type ii silver plate per ams2410 or ams2411or cadmium plate per saeams qqp416 type ii, class 2 solid film lubricant per as5272, type i, applied to threads only (a) minimum thread h in short lengths minimum thread h where length permits shall be 2 x diameter of thread

Part Number Ajb 10tfa 018 Ajb Tfa Tfc Flanged Journal Bearings Sae As 2 On The Timken Company

Oem Spec Description Abex Ps102 Passivate Aero Union Corporation Aups 7 04 Topcoat Aero Union Corporation Aups Topcoat Aerofit Inc Pdf Free Download

Approvals – California Technical Plating Corp Prime Approvals Cadmium, Electrodeposited QQP416 Types I, II CalTef SP1000 Chemical Conversion Coating MILC5541 Class 1A, Class 32 QQP416, AMSQQP416, AMS 2400, MILSTD870 Chemical Film Types 1 &QQP416F 3292 Phosphate treatment Unless otherwise specified in the contract or order (see 62), the phosphate treatment required for conversion to Type III shall produce a tightly adherent film conforming to Type I of TTC490 33 Detail requirements 331 Thickness of plating Unless otherwise specified (see 62), the

2

Washers Pdf

Enhanced durability Gold plating deposits a thin layer of gold onto the surface of another metal, by chemical or electrochemical plating With only a thin layer of gold required, it can be costRKEL W W VKEL To meet AS requirements Y ZincCobalt, Dark Olive drab ASTMB840I have a question and someone can help clarifying the definition of a lot in accordance with AMSQQP416 Para 4421 as follow Lot shall consist of plated articles of the same basis metal composition, class, and type plated and treated under the same conditions and submitted for inspection at one time

Isgroup International Com

Aeronautical Std Steel Nut Plain Castellated Hexagon An310 8 Pilots Hq Llc

2Black Cadmium Plate in accordance with QQP416 link by ed to spec at Defense Logistics Agency, dlamil,type 2,class i Is it alright if I do electroless nickel plating?SAE AMSQQP416, Revision F, March 21 (R) Plating, Cadmium (Electrodeposited) General Usage Processes used for cleaning and cadmium deposition on components heattreated to, or having ultimate tensile strength of 152 ksi (1048 MPa) or higher tensile strength or 34 HRC or higher, should incorporate practices and procedures to minimize hydrogen embrittlementFlat Head Machine Screw with Plate per QQP416, Type II 100 Degree Check up to five results to perform an action larger image Results Per Page 25 50 100 0 Results 1 25 of 94

Rj45 Connectors Rj45 Connectors Interconnect Solutions Worldwide Pdf Free Download

Fleet Readiness Center Southeast Technology Electroplating Chrome Plating Ams Qq P 3 Ams 2460 Pdf Document

Also known as SAE AMSQQP 416 SAE MOBILUS Subscribers can view annotate, and download all of SAE's content Learn More »Other Rack Gold Plating Brass;Qqp416f (notice 1), federal specification plating, cadmium (electrodeposited) (28 mar 02) s/s by saeamsqqp416 Future acquisition for this item should refer to SAEAMSQQP416, "Plating Cadmium (Electrodeposited)" (Application for copies of SAE Aerospace Material Specifications should be addressed to SAE, 400 Commonwealth Drive

Cadmium Plating Sheffield Platers

Ams Qq P 416 Cadmium Plating Coating Services Incertec

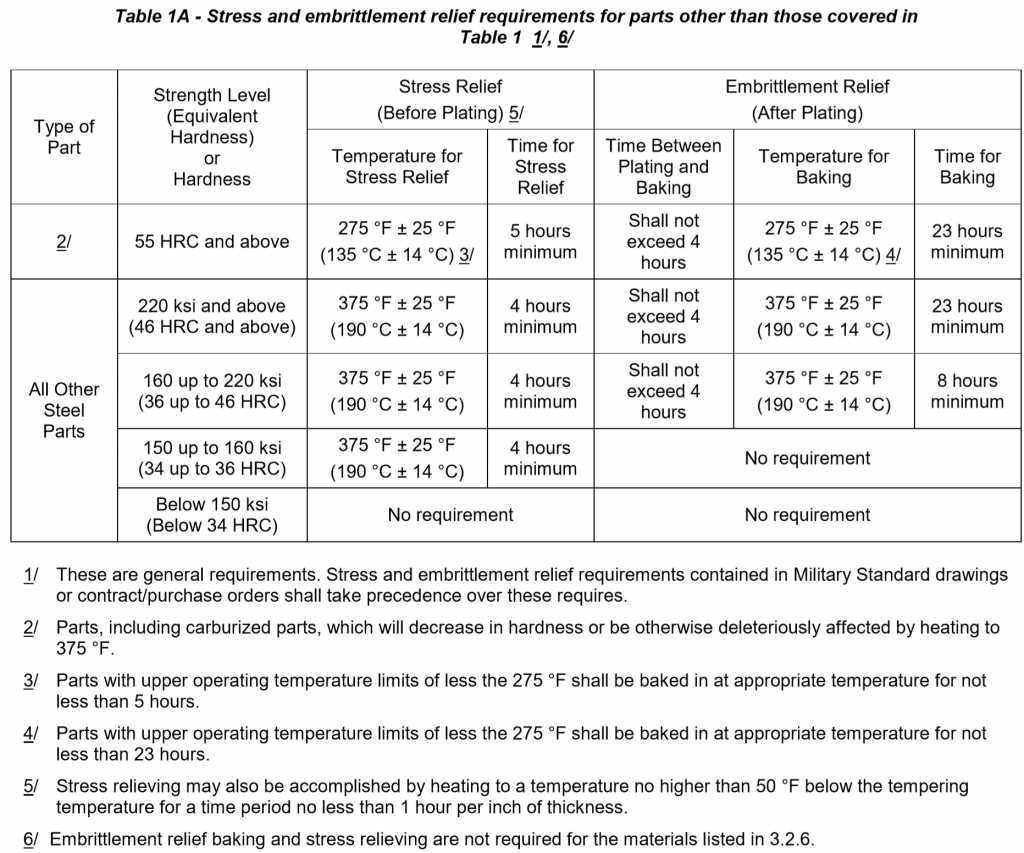

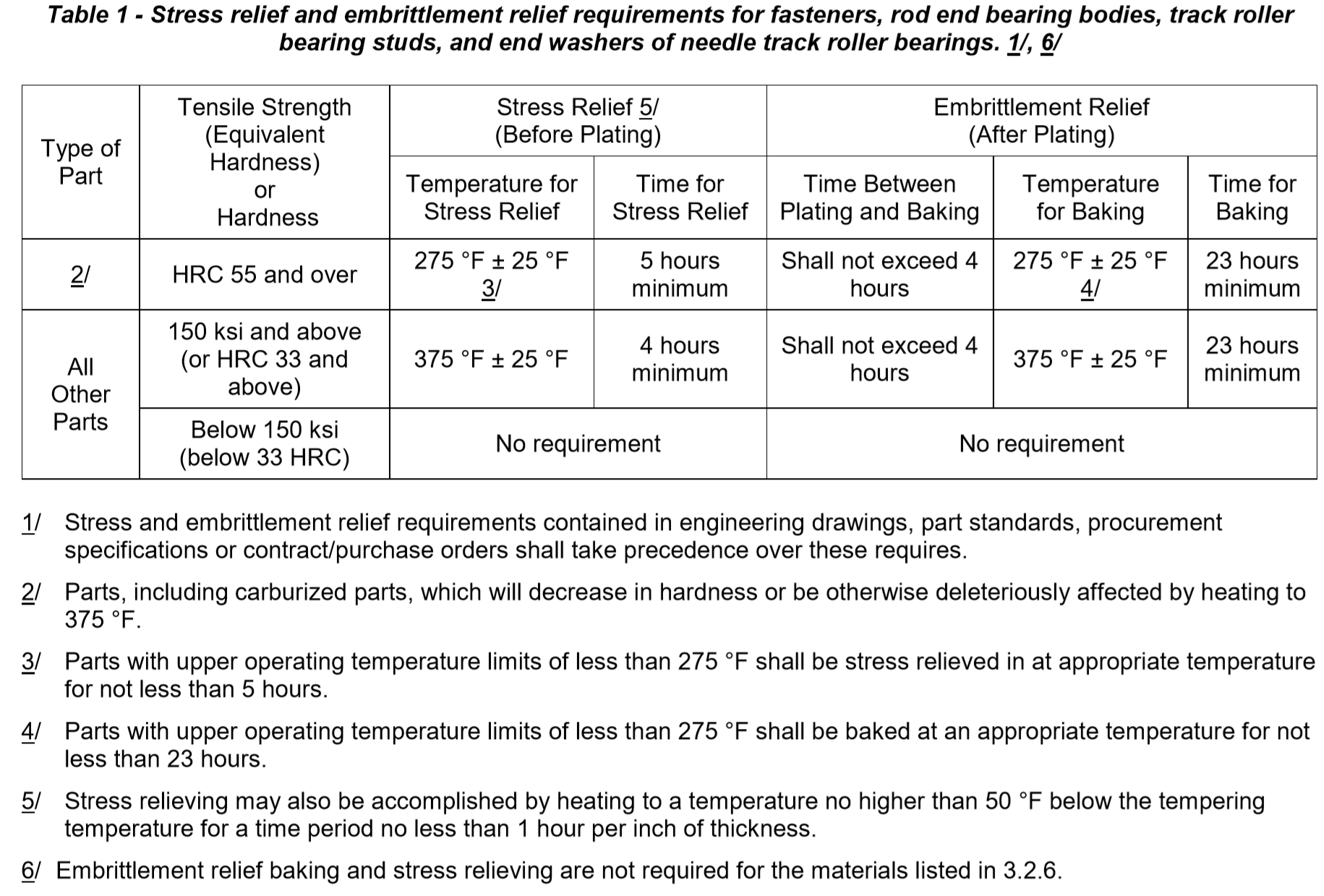

TYPE OF PROCESS SPECIFICATION Bright Nickel AMS 2403, QQN290, AMSQQN290 Brush Plating MILSTD865 Cadmium Plate Types 1 &Federal Specification QQP416 We offer a wide range of specialist cadmium plating services, including federal specification QQP416, covering the scope of electrodeposited cadmium plating Class 1 THICKNESS " min Class 2 THICKNESS " min Class 3 THICKNESS 000" min Type I DETAIL As plated, no chromateRevision E of AMSQQP416 corrects the errors in Table 1a and removes the "24 hours minimum" from the drying time requirement of 3281

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Ms Unc Unf Pan Head Las Aerospace Ltd

Cadmium Plating Cadmium is a soft white metal, when electrodeposited onto ferrous and nonferrous base metals (steel and copper), functions as a "sacrificial coating", corroding before the substrate material to which it is applied Cadmium offers an exceptional bonding surface for adhesives and paints, and is the preferred coating for saltCoating Specs AMSQQP416 Technical Advantages Good protection against corrosion in salt atmospheres and at low thickness Resistant to mold and bacteria growth Low electrical resistance and exceptional conductivity Favorable galvanic compatibility with aluminum Natural lubricity providing antigalling and lowfriction propertiesSince appropriate black passivation material is not available,is it alright if I do zinc plating over the cadmium plating and then do black passivation?

Aerospacebolts Instagram Posts Photos And Videos Picuki Com

Monadnock Floating Clip Nut Sku Mndnck Clpnut

Cadmium plating provides a smooth, adherent surface that is free from blisters, pits, nodules, burning, or other defects when examined visually without magnification It also provides great corrosion resistance Contact ENS Technology for more information regarding FED QQP35C cadmium plating todayQQP416 Type 1, 2;2 FSC 5310 ITEM NAME Washer, Lock, FlatInternal Tooth ITEM NAME CODE (INC) SPECIFICATION MS MATERIAL Carbon SteelComposition 1, FFW100 FINISH Cadmium QQP416 Type II, Class 2 Note LockWashers considered for use in Electrical Components

Pia Com

Tye03 Hole Datasheet Pdf Clearance Hole Equivalent Catalog

P/N MS Description stud #6, copper, cadmium type II, designed to be used with terminal block (MS), the last number indicates number of stud holes in assembly, terminal link, MS series conductor Qqp416, Type 2, ClassQQP416 F Type I No supplementary treatment Type II Supplementary chromate treatment Type III Supllementary phosphate treatment Class ″ min Class 003″ min Class ″ min QUALITY * SERVICE * COMPETITIVE PRICING View AllQqp416, type ii, class 2113 cadmium (yellow chromate)000 min qqp416, type ii, class 3181 zinc min no under plate necessary qqz325, type i

Flamecorp Com

Thin Dense Chrome Plating Cadmium Plating Ams Qq C 3 Ams Qq P 416

3) MILC5541, AMSC5541, AMS 2473, MILDTL5541Cadmium Plated, AMSQQP416, TYPE II, CLASS 2 Thread Specs 1032 UNF3A Locking Mechanism None The prints &Aluminum Alloy 6061 In Accordance With SAE AMSQQ50/11 Plating code 1 cadmium with yellow chromate conversion coating in accordance with SAEAMSQQP416, Type II, Class 3 Plating code 2 electroless nickel in accordance with ASTM 33 Plating code 4 black anodize in accordance with MILA8625 Type II Class 2

We Are An Iso 9001 15 Certified Supplier Of Custom Military And Defense Fasteners Like These Custom Nsn 01 093 0290 Nsn 5305 01 093 2450 Aerospace Screws

D7118

Data found here within are not to be used for the manufacturer, procurement, or use of this product They are for educational proposes only DRAWING(S) PDF Drawing of AN46A SeriesWhere electrodeposited cadmium plating per QQP416 is specified, vacuum deposited cadmium plating per MILC87, Type II, Class 2 may be substituted NOTE Vacuum cadmium plating of all steel parts heat treated above 180,000 psi requires Gulfstream Technical Operations review andT Cadmium, Bright AMSQQP416, TypeI, Class2 5 Cadmium, Olive drab AMSQQP416, Type II, Class 3 V VKEL AMSQQP416, TypeII, Class3 (Cadmium);

Performance Of Three Alternating Coatings

Nas1581 Bolt Datasheet Pdf Head Bolt Equivalent Catalog

THICKNESS PER CLASS I – ″ minimum II – ″ minimum III – ″ minimum PLATING TYPES Type I – as plated Type II – w/ supplementary Chromate treatment INDUSTRY USES Aerospace, Automotive, Electronics, Defense, Marine and more2 QQP416, AMSQQP416, AMS 2400 Cadmium Low Embrittlement Types 1 &Nickel alloys Bright gold;

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Cadmium Plating New Method Plating Company Inc

CAD PLAte QQP416 tyPe II CLeAR DIChRoMAte, CLASS 2 PASSIvAte AMS 2700 PASSIvAte AMS 2700 NoNe oR DICRoNIte DL5 Lock Collar "" type "" Signifies that the 5/3 and 3/16 diameter sizes are installed with a double action (shifting type) tool Shift Washer Lock Collar "s" type "S" Signifies that the fastener isCadmium Plated, AMSQQP416, TYPE II, CLASS 2 Thread Specs 1/428 UNF3A Locking Mechanism None The prints &Reference # 2F52N Product Description UNJF3B Nut Hex, High Tensile, Steel Steel Type C1137 OF FEDSTD66 or Carbon or Alloy Steel MILS1222 (C1137 Steel May Contain from 015 TO 035 perCENT LEAD), Cadmium Plate, SAEAMSQQ P416 Type II, Class 2 N1610 Series Product certifications may be available for this product

1

2

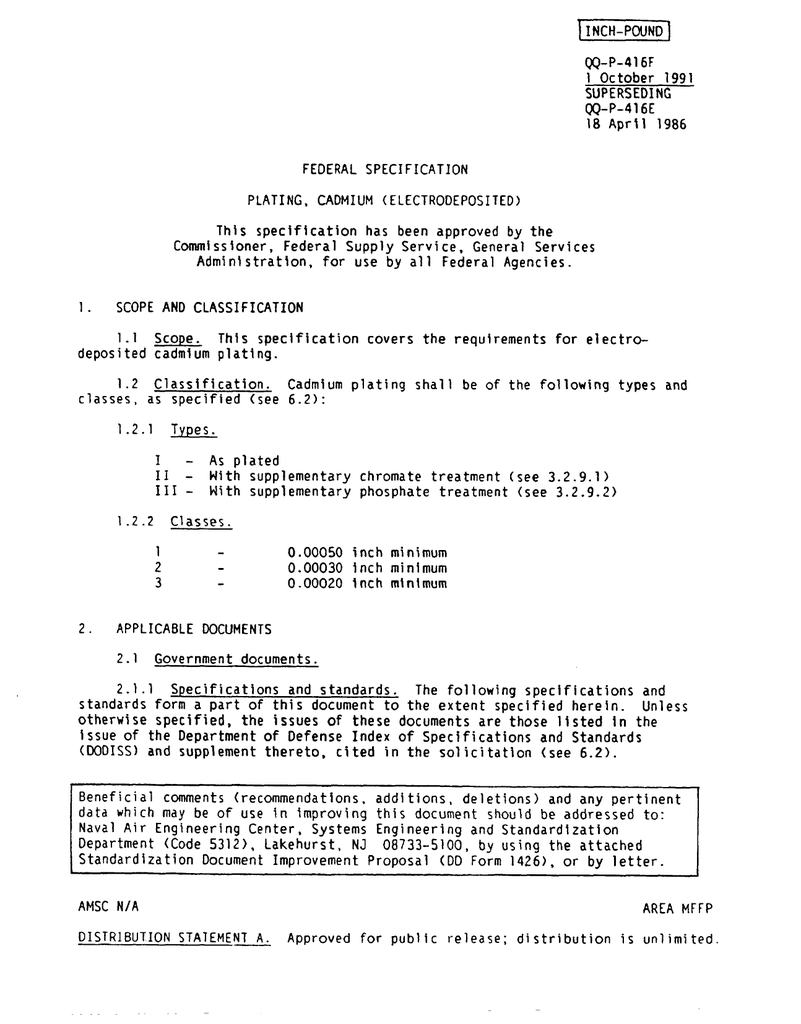

QQP416F, FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (01 OCT 1991) S/S BY SAEAMSQQP416, This specification covers the requirements for electrodeposited cadmium plating

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Dust Cap For Receptacle Mil Dtl 399 Series Ii

Mil Spec Washers 10 Ms Military Split Lock Washer Fastenerexpert Us

3

Seastrom Mfg Com

Hex40 Ab 90 11 2 Raychem Screened Backshells Adapters Te Connectivity

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

2

Ms356 Series Pan Head Phillips Machine Screw Repl An515r Series Sku Scrw Ms356 An515r

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Ams Qq P 416

Plating Specifications General Information Pdf Free Download

Approvals California Technical Plating Corp

Sae Ams Qq P 416 R Plating Cadmium Electrodeposited

Qq P 416 Cadmium Plating Keystone Finishing

Oem Spec Description Abex Ps102 Passivate Aero Union Corporation Aups 7 04 Topcoat Aero Union Corporation Aups Topcoat Aerofit Inc Pdf Free Download

Nas1352 Pdf Nas1352 데이터시트 Nas1352 데이타시트

Everyspec Com

The Best Online Store Offer Sxs10k166cy Rivetnut 10 32 116 166 Gr Rnd Body Csk Hd Keyed Steel Cad Ylw 50 Pk Industrial Scientific Is Discounted Sonoritaaparelhosauditivos Com Br

Parker Com

2

深圳市伟健电子科技有限公司

2

Datasheet Datasheetarchive Com

Nas64 4 Lfc Supply Shield

Nasm Datasheet Pdf Datasheet4u Com

2

Cadmium Plating Color

2

Qq P 416 Tech Information

2

Nasm Nut Datasheet Pdf Nut Equivalent Catalog

2

Page 367 Is Rayfast Catalogue Issue 9 17

Pia Com

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Ansi B18 2 3 Pdf Document

Qq P 416 F Pdf Corrosion Specification Technical Standard

2

Mil Spec Disc Springs Mil Spec Springs

Cadmium Plating Sheffield Platers

Flathead Threaded Insert Open End Keyless Metric On Pennengineering

2

Cadmium Plating Macon Georgia

Cadmium Plating Alternatives

Amazon Com 4 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class 2 Pack Qty 5 000 Ms 40cd By Shorpioen Industrial Scientific

1

Te Com

Qq P

Clarke Com Au

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Pccfasteners Com

Cadmium Plating Sheffield Platers

Page 317 Fiber Optic Connectors Termini And Cables Glenair

Page 16 Circular Connector Backshells And Accessories

Cadmium Plating Sheffield Platers

Qq P 416 Tech Information

6 Ms Military Split Lock Washer Cad Ii Per Qq P 416 Type 2 Class Bolt Demon

2

2

Countersunk Head Threaded Insert Closed End Keyless Unified On Pennengineering

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

Buerklin Com

Pccfasteners Com

Evaluation Of Alternatives To Electrodeposited Cadmium For Alcoa

Cadmium Nadcap Co Operative Plating

Ns Yb05c Controller Datasheet Pdf Display Controller Equivalent Catalog

Aeronautical Std Steel Nut Plain Castellated Hexagon An310 7 Pilots Hq Llc

Cadmium Plating For The Aerospace Industry Har Conn

Alliedelec Com

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Speedcomfly Com

コメント

コメントを投稿